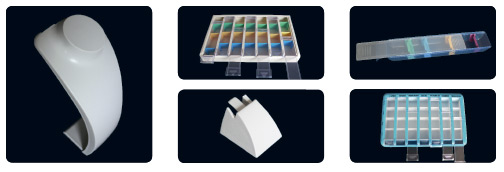

Thermoplastic injection processes

Each design corresponds to a particular customized manufacturing process, based on the specific needs of each customer. Colour, transparency, resistance, etc – each parameter is taken into account to meet the different requirements and optimize product characteristics in line with the predefined objectives and sector of activity (medical, building, equipment, sport and so on).

To obtain your free quote, contact us !

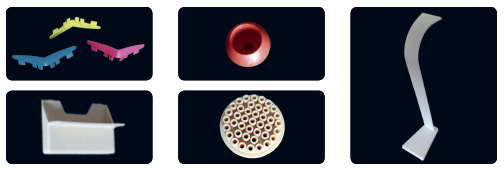

A few examples of materials used

ABS (Acrylonitrile Butadiene Styrene)

ELASTOMER (Rubber)

POLYAMIDE

Up to 40% FV Noryl charged, not charged or laquerable.

PMMA / POLYCARBONATE

POLYPRO – PEHD – PP TALC

PVC (Polyvinyl chloride)

DUPLICATE MOULDING / ULTRASONIC SEALING